Aerogel, often referred to as “frozen smoke” or “frozen air,” is a superlight, porous solid material with extremely low thermal conductivity. It is made from silica gel, in which the liquid part of the gel is replaced by gas, creating a porous structure with countless microscopic pores. It is this structure that gives aerogel its special properties, making it one of the most effective insulating materials available today.

Aerogel Structure and Properties

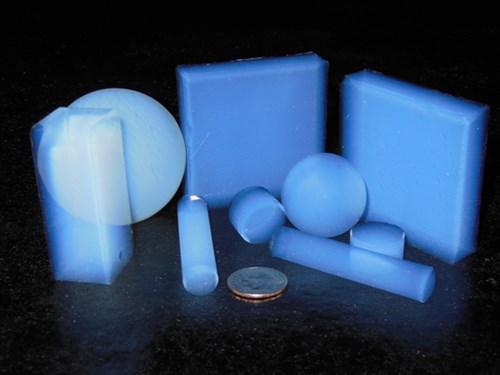

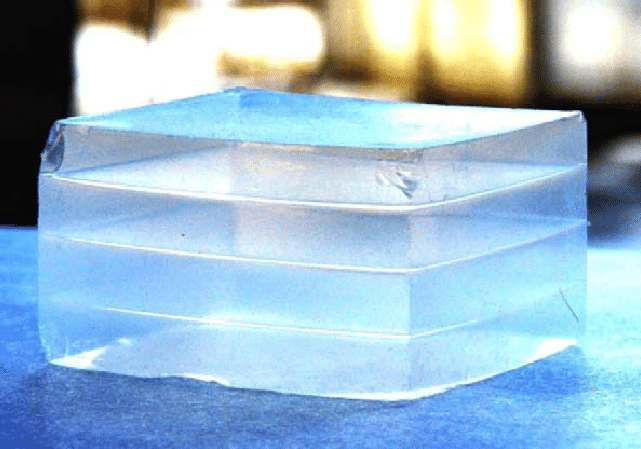

-Porous Structure: Aerogel has a porous structure with countless microscopic pores, accounting for up to 99% of the volume. It is this structure that gives aerogel its extremely light weight and excellent thermal insulation properties.

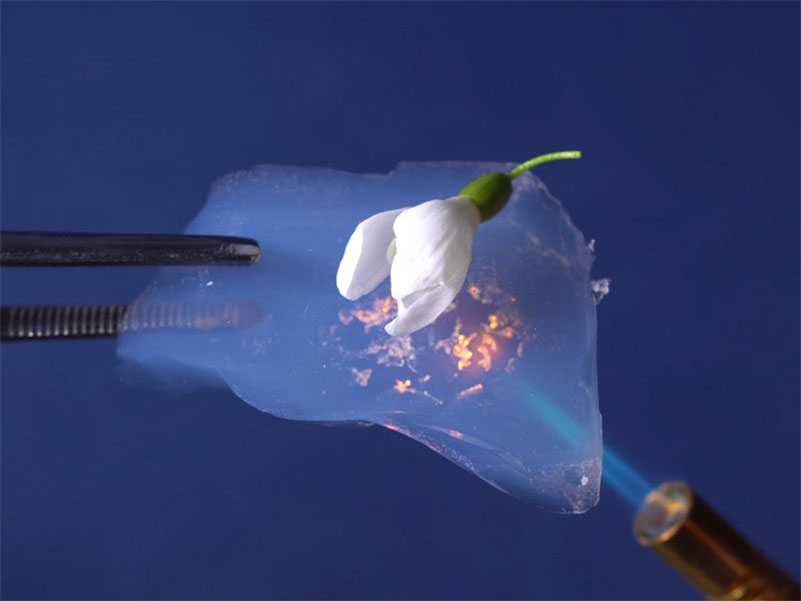

-Extremely low thermal conductivity: Aerogel is one of the materials with the lowest thermal conductivity in the world. This means it is very poor at transferring heat, helping to keep warm in the winter and cool in the summer.

-High strength: Although very light and porous, aerogel is highly durable and can withstand great pressure.

-Transparency: Aerogel can be transparent or opaque, depending on the manufacturing process.

– Inertness: Aerogel does not react with most chemicals and is harmless to human health.

Applications of Aerogels in life

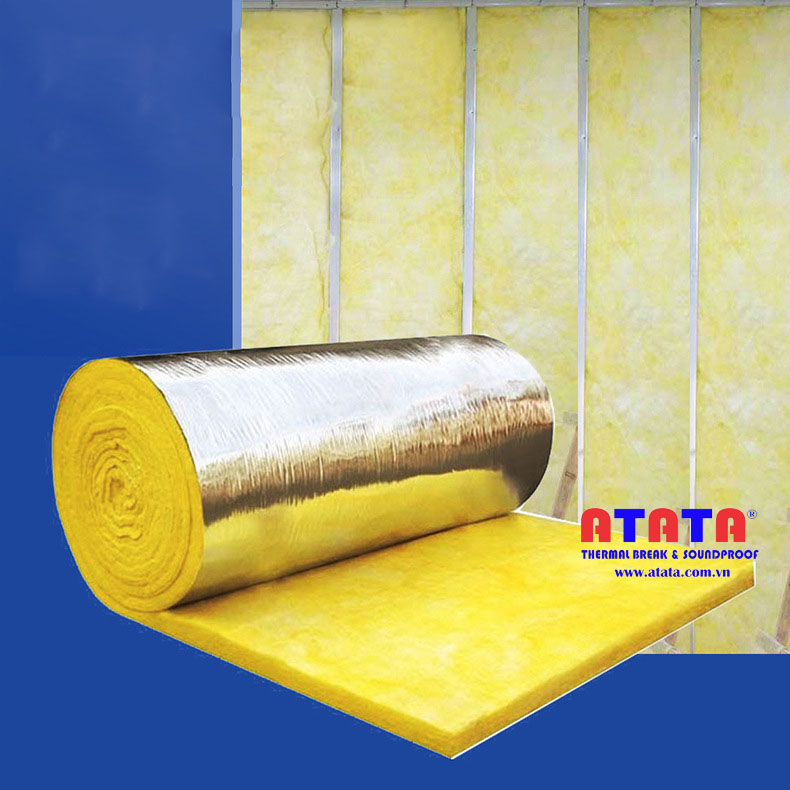

Insulation: Aerogels are widely used in insulation applications, such as insulation for buildings, pipes, electronic equipment, and even protective clothing.

Aerospace: Aerogels are used in spacecraft to collect cosmic dust and insulate equipment.

Construction materials: Aerogels are used to produce building materials with high insulation properties.

Cosmetics: Aerogels are used in some cosmetic products such as sunscreens and skin creams.

Aerogel applications for pipelines

Steam pipelines: Aerogel helps minimize condensation on the pipeline surface, preventing corrosion and increasing the life of the pipeline.

Oil pipelines: Protect oil from temperature changes, reduce heat loss and increase transportation efficiency.

Gas pipelines: Minimize heat loss, especially in compressed air systems.

Cold liquid pipelines: Keep the temperature of the liquid stable, preventing ice formation.

Pipelines in HVAC systems: Improve the efficiency of heating, ventilation and air conditioning systems.

Pipelines in chemical plants: Protect pipelines from the effects of corrosive chemicals.

Advantages of Aerogel

Excellent insulation: Helps save energy and reduce heating/cooling costs.

Super light: Reduces the load on the structure.

Durable: Has a long life.

Safe for health and the environment.

Flexible: Easy to bend and cut to pipe size.

Fire resistance: Aerogel has high heat resistance.

Disadvantages of Aerogel

High cost: The aerogel production process is complicated and requires high technology, leading to a relatively high product cost.

Construction: High technical requirements during construction to ensure insulation efficiency.

Comparison of Aeragel and glass wool

| Features | Aerogel | Glasswool | Polyurethane foam |

| Thermal conductivity | Very low | Low | Medium |

| Mass | Super light | Light | Heavier |

| Durability | High | Medium | Medium |

| Cost | High | Medium | Low |

Future of Aerogel

With its special properties, aerogel is expected to have many applications in the future, especially in the fields of energy and environment. Scientists are constantly researching to reduce production costs and improve the properties of aerogel, in order to expand the scope of application of this material.

Contact

DETI CO ., LTD

Factory : Atata Building, Yen Son IZ , Quoc Oai Dist, Ha Noi City

Office : Shop-House b5-20, Vinhomes Gardenia Ham Nghi, Nam Tu Liem District, Ha Noi City.

Hotline : 0913.554.030 – 0904 698 379 – 0936 382 469

Website : prodetech.vn ; beeflex.com.vn ; nanoflex.com.vn ;atata.com.vn ; 3wtape.vn ; microflex.com.vn