1 The method of bending copper pipes does not depend on many factors, including the quality of copper pipes, precise bending techniques as well as guaranteed bending tools. 2 Selecting a quality copper pipe 3 Some terms to note when performing copper pipe bending 3.1 What is the bending angle? 3.2 What is the radius center line? 3.3 What is the maximum degree of bend? 3.4 Bending pipe series? 3.5 Tools needed when bending pipes?

The method of bending copper pipes depends on many factors, including the quality of copper pipes, precise bending techniques as well as guaranteed bending tools.

Selection of quality copper pipes

Choosing to buy good copper pipes for bending is not easy. Cheap gravure products are not always good quality products. Most of the market on cheap copper products often have a lot of impurities added.

Nguyên liệu của ống kém cho nên kéo theo góc uốn của ống cũng kém chất lượng. Ống đồng uốn bị bẹp, dễ bị vỡ và hư hại ngay cả khi bạn có sử dụng những công cụ, máy móc hỗ trợ tiên tiến nhất và tốt nhất cũng không thể bù đắp lại phần nguyên liệu kém chất lượng làm ống.

The material of the tube is poor so the bend angle of the pipe is also poor quality. Bending copper pipes are crushed, prone to breakage and damage, even if you use the most advanced and best tools and support devices, they can not compensate for the poor quality raw materials for making pipes.

Some terms to note when performing copper pipe bending

There are many methods for bending pipes and pipes but the process to achieve high results at reasonable costs, it is recommended to choose the method of bending drawn pipes.

What is the bending angle?

The first form of a bend is to draw around a blank of the workpiece. Bend a piece of force that must be balanced. The first edge of the material to be bent is clamped to bend into a fixed shape, while between dead formed grooves and opposing forces, often called pressure bends. Forming the rotary die at the desired level of curvature completes this process.

Based on your requirements and income, you can choose this bending process to save more cost than some other methods.

What is the radius center line?

The center line CLR radius is often referred to as the distance from the center of the mold to the center line of the material being bent. This gap is often over looked but it is actually important for determining the appropriate bending angle required when bending copper pipes.

Factors such as: the layer of materials to be bent, thickness, type of bending used, and support tools have certain effects on CLR. When using CLR to measure the bend technique, copper tube products after bending are more beautiful than using normal eyes.

Using double bending of materials with CLR requires a much higher fee than other methods, so choosing CLR should also be considered carefully. Although it brings a lot more sophistication than other methods.

What is the maximum degree of bend?

Following the common definitions the maximum level sounds simple. But just a little neglect you can be miscalculated and can not calculate the maximum bending angle. Without getting the maximum bending angle you will not have the parameters to make the next bending.

The acceptable tool design has a maximum bending angle of 180 degrees. With this dimension, a bending machine can measure and calculate to provide information about which angle bend is standard, which angle is easier to use.

New materials when used for bending are usually tested at 45-degree and 180-degree bends. In the embryos will produce different results, the greater the bend angle, the thinner the production and often cause material deformation. So the maximum degree of bending greatly influences the quality of the bend and the deformed shape in the material.

Bending pipe series?

The overall time cycle is different from the actual time period of bend. The actual cycle time of bending is negligible due to different work requirements, sizes, and productivity.

In order to consider and estimate the actual time, it is necessary to consider factors such as documentation, coordination ability, computer positioning time and bending speed. Activities such as cutting, grinding, and welding also need to be calibrated to meet the productivity goals set for a bending machine.

Tools needed when bending pipes?

Joining the pipe bending process needs a variety of bending tools from available materials, materials supplied from the manufacturer, materials of difference in quality … The manufacturer is always ready to meet the tools. to be discussed and advised. The final decision is to provide you with the most appropriate tool.

The CLR resizing tool standard is quite high. First of all, to use special equipment, you must pay first, the cost is high and the time is long. To avoid the hassle and save a lot of money as well as the time it takes effort.

Material samples are being encouraged to produce more than just choosing one to produce. Use specific order printing with each special tool to avoid mistakes.

Please grasp these terms clearly so you can practice how to drink copper pipes without being crushed. Good luck!

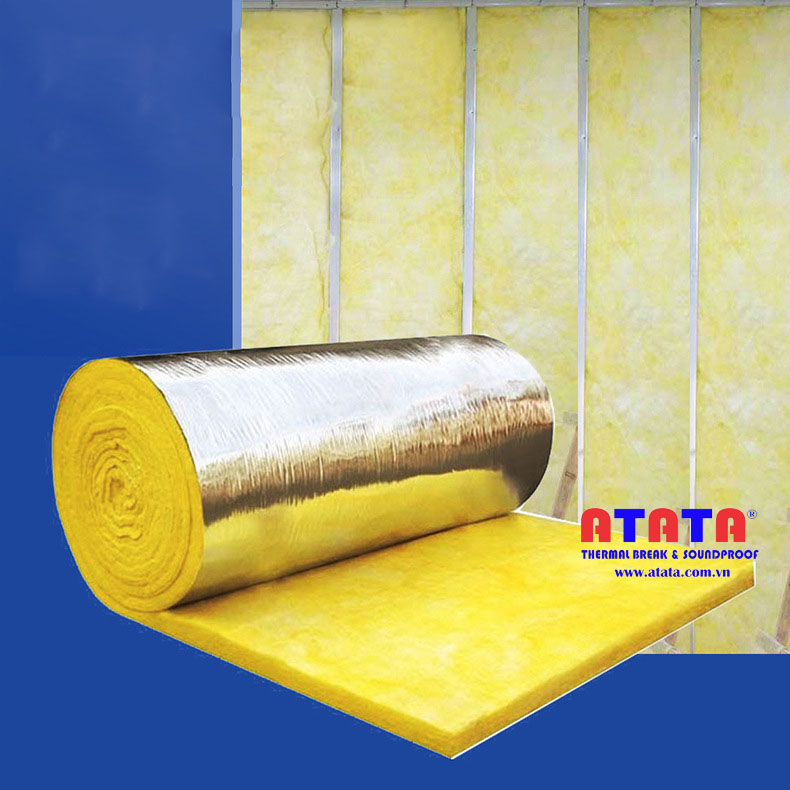

tag : Bảo ôn; bao on; bảo ôn ống đồng; bảo ôn ATATA; bảo ôn cách nhiệt; bảo ôn ống thép ; bảo ôn đường ống ; bảo ôn ống gió; bảo ôn ống nước; bảo ôn cho ống chiller ; bảo ôn định hình; bảo ôn có lớp bạc; bảo ôn chống cháy ; ống có lớp nhôm; tấm cách nhiệt ; tấm bảo ôn, tấm cách nhiệt có keo dính ; tấm cách nhiệt có lớp bạc ; tấm có keo; bảo ôn cuộn; bảo ôn tấm; bảo ôn tấm ATATA; tiêu âm ; tieu am; cách âm; cach am;