Sound-absorbing rubber foam is a popular material used in a variety of industries to reduce noise and improve sound quality. From recording studios to industrial facilities, this versatile material is known for its ability to absorb sound and reduce reverberation. But does sound-absorbing rubber foam really work? Let’s dive into the science behind this material and explore its effectiveness in different applications.

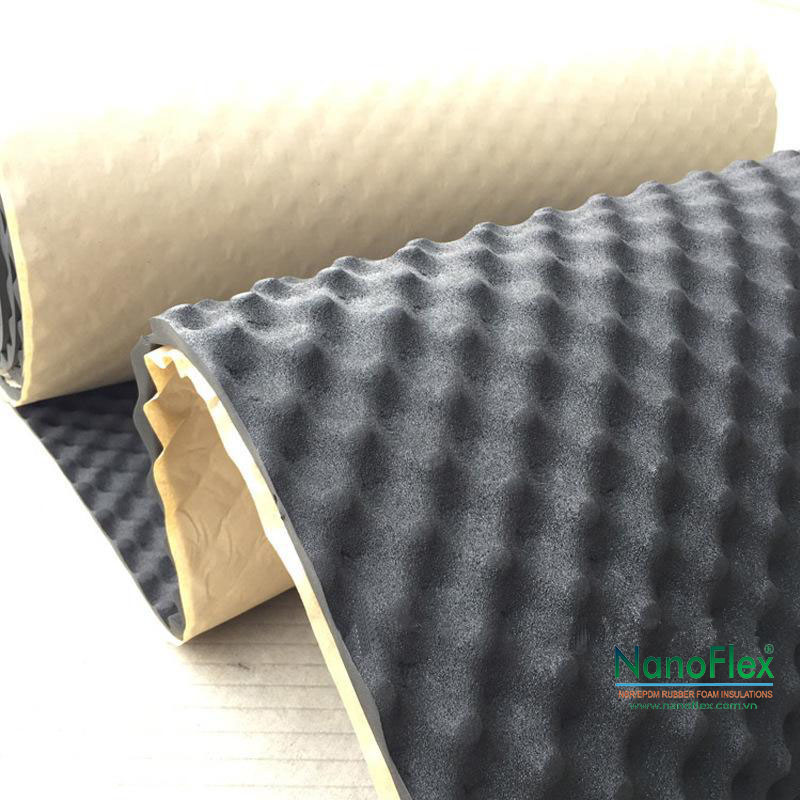

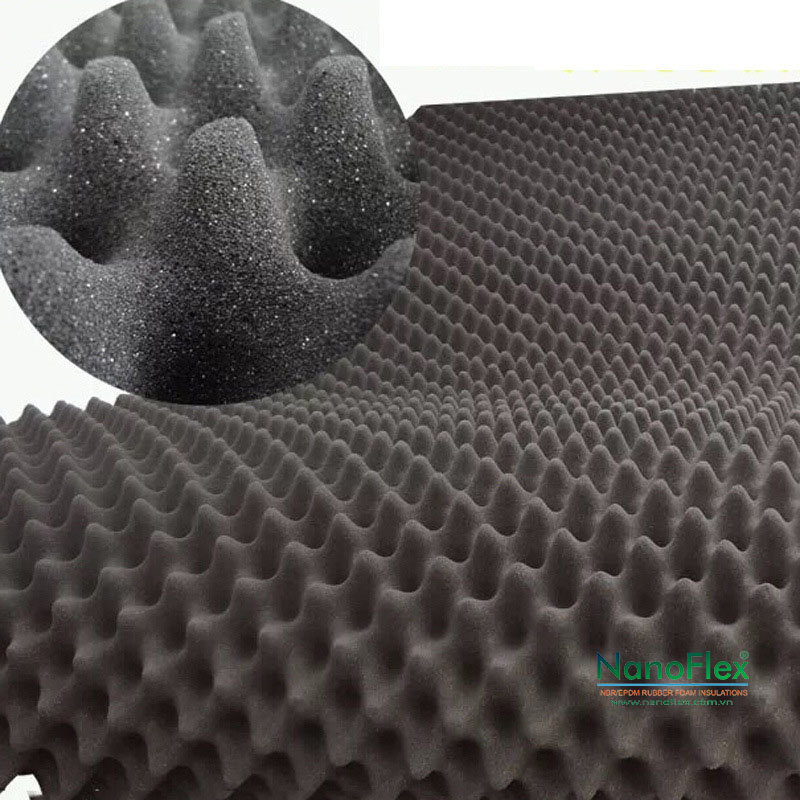

Sound-absorbing rubber foam, also known as acoustic foam, reduces the propagation of sound waves by absorbing them as they pass through the material. This is achieved through the foam’s open-cell structure, which allows sound waves to enter and dissipate within the foam, rather than bounce off a hard surface and create an echo. The porous nature and irregular surface of the foam help break up the sound waves, converting them into heat energy and reducing their intensity.

One of the key factors that determines the effectiveness of sound-absorbing rubber foam is its density. Foam with a higher density generally has better sound absorption properties because it provides more mass to block and absorb sound waves. In addition, the thickness and surface area of the foam also play a crucial role in determining its sound absorption capabilities. Thick foam with a larger surface area can absorb a wider range of frequencies and provide better overall sound control.

Acoustic rubber foam is widely used in recording studios, home theaters, and other audio-sensitive environments to improve sound quality and reduce unwanted noise. In these environments, foam is strategically placed on walls, ceilings, and floors to minimize sound reflections and create a more controlled acoustic environment. By absorbing excess sound energy, the foam helps improve the clarity of recordings and create a more pleasant listening experience.

Beyond the entertainment sector, acoustic rubber foam also has a place in industrial settings where noise control is a top priority. Machinery in factories and manufacturing facilities often generate high levels of noise, which can disrupt workers’ physical and mental health and damage their hearing. By installing acoustic foam in these environments, the effects of noise can be significantly reduced, creating a safer and more comfortable work environment.

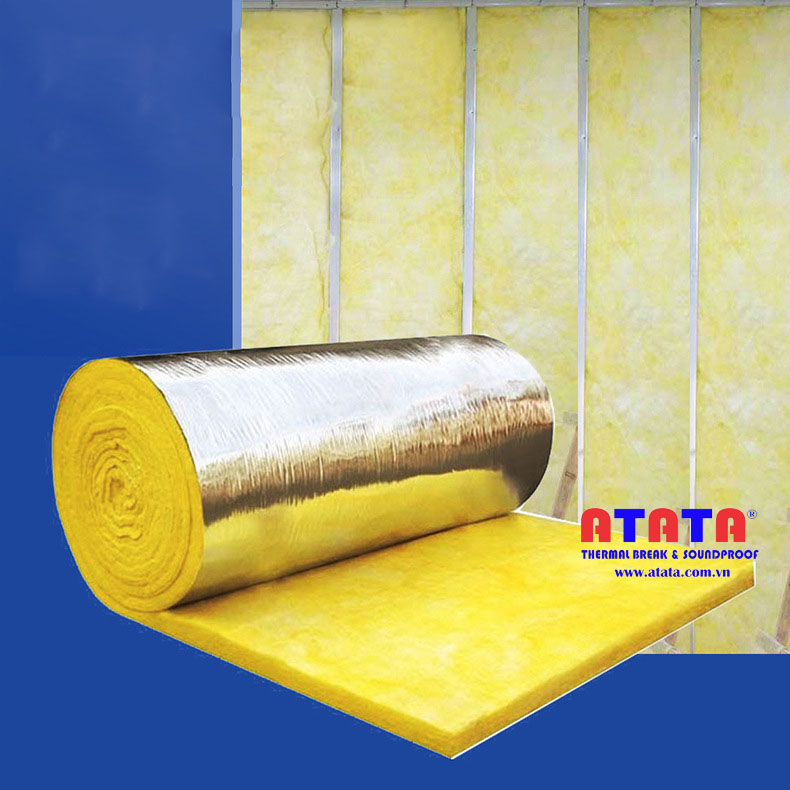

In addition to noise control, acoustic rubber foam also has thermal insulation benefits. The same properties that make it effective at absorbing sound also make it an excellent insulator for temperature and energy control. This dual functionality makes it a valuable material for applications that require both sound absorption and thermal insulation, such as HVAC systems, automotive interiors, and building construction.

While acoustic rubber foam offers many benefits, it is important to note that its effectiveness can be affected by a variety of factors, including the specific environment, type of noise, and installation method. In some cases, additional soundproofing materials or techniques may be required for optimal results. It is also important to consider fire safety regulations and ensure that the foam used meets the standards required for flammability.

Acoustic rubber foam can be used to reduce noise and improve sound quality in a variety of applications. Its ability to absorb sound waves, minimize reverberation, and provide thermal insulation makes it a valuable material for creating more comfortable and functional spaces. While it may not completely eliminate all noise, acoustic rubber foam can make a significant difference in controlling and managing sound levels if used properly. Whether it is in a recording studio, industrial facility, or home theater, using acoustic rubber foam can help create a more comfortable and productive environment.

Contact

Factory : Atata Building, Yen Son IZ , Quoc Oai Dist, Ha Noi City

Office : Shop-House b5-20, Vinhomes Gardenia Ham Nghi, Nam Tu Liem District, Ha Noi City.

Hotline : 0913.554.030 – 0904 698 379 – 0936 382 469

Website : prodetech.vn ; beeflex.com.vn ; nanoflex.com.vn ;atata.com.vn ; microflex.com.vn