The application of foam rubber insulation materials in construction is becoming more and more popular to improve energy efficiency and the quality of living space. To ensure the construction process is optimally effective, the following steps are presented in detail:

Preparation:

Materials:

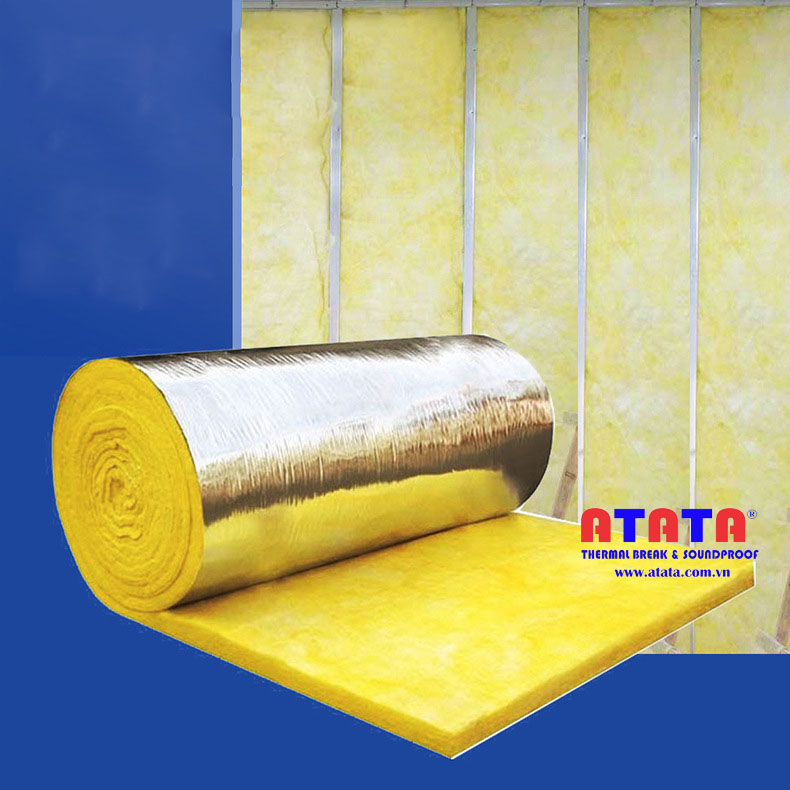

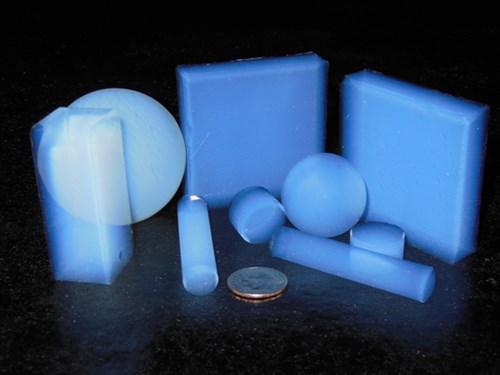

Foam rubber insulation panels: choose the type with density and thickness suitable for the technical requirements of the project.

Specialized glue: use glue with good adhesion on both the wall surface and foam rubber, ensuring the durability of the insulation layer.

Aluminum tape: used to seal joints, creating a tight and tight connection.

Tools: tape measure, specialized cutter, roller, glue trowel, drill (if needed).

Construction surface:

Cleaning: Thoroughly clean the wall surface to remove dirt and grease, ensuring the best adhesion for the adhesive layer.

Surface treatment: Repair cracks and holes on the wall surface with suitable materials.

Construction steps:

Measure and cut the panels:

Accurately measure the dimensions of the locations to be constructed.

Use a specialized cutting knife to cut the foam rubber panels according to the measured dimensions, ensuring the cut edges are straight and perpendicular.

Surface preparation:

Flattening: Use a layer of putty to create a flat, even surface for the wall, especially for areas with high roughness.

Create roughness: Give the wall surface a slight roughness to increase the adhesion of the adhesive layer.

Glue application:

Use a putty trowel to spread a thin, even layer of glue onto the wall surface.

Note: Do not apply too much glue to avoid overflow and peeling.

Sticking foam rubber sheet:

Place the cut foam rubber sheet on the wall surface that has been glued, gently press firmly to ensure the entire surface is in contact with the glue layer.

Use a roller: Use a roller to roll thoroughly to completely remove air bubbles and create a tight bond between the foam rubber sheet and the wall surface.

Joint treatment:

For adjacent foam rubber sheets, use aluminum tape to overlap the edges, ensuring tightness and aesthetics.

Finishing:

Carefully check the entire constructed surface, making sure there are no peeling, gaps or air bubbles.

Note:

Choose the right type of glue: Should use a specialized glue for foam rubber, which can withstand high temperatures and humidity.

Preserve foam rubber: Before construction, leave the foam rubber at room temperature for about 24 hours for the product to achieve the best effect.

Labor safety: When constructing, it is necessary to fully equip labor protection equipment such as masks and gloves to protect health.

Environmental conditions: Foam rubber should be constructed in dry weather conditions, avoiding rain or high humidity.

Conclusion:

The construction of foam rubber insulation materials requires meticulousness and high technique. By following the correct construction process, you will have a quality insulation layer, contributing to improving the efficiency and life of the project.

We are always ready to support customers in choosing insulation materials.

Contact

DETI CO ., LTD

Factory : Atata Building, Yen Son IZ , Quoc Oai Dist, Ha Noi City

Office : Shop-House b5-20, Vinhomes Gardenia Ham Nghi, Nam Tu Liem District, Ha Noi City.

Hotline : 0913.554.030 – 0904 698 379 – 0936 382 469

Website : prodetech.vn ; beeflex.com.vn ; nanoflex.com.vn ;atata.com.vn ; 3wtape.vn ; microflex.com.vn