Why insulate piping hot and cold?

– Energy saving: Insulation reduces energy costs

– Impressive return on investment: Insulation is a quick payback

– Condenser control with insulation

– Process control with insulation

– Protect the environment by reducing emissions

– Human resource protection

– Fire protection

– Improved appearance

– Noise control with insulation

– Increase space efficiency with insulation

Direction of insulation pipe hot and cold

– What materials to prepare for construction?

– Safety equipment for workers / engineers what?

– Note when done

Insulation process for hot and cold pipes

– Stage 1: Clean pipe surface

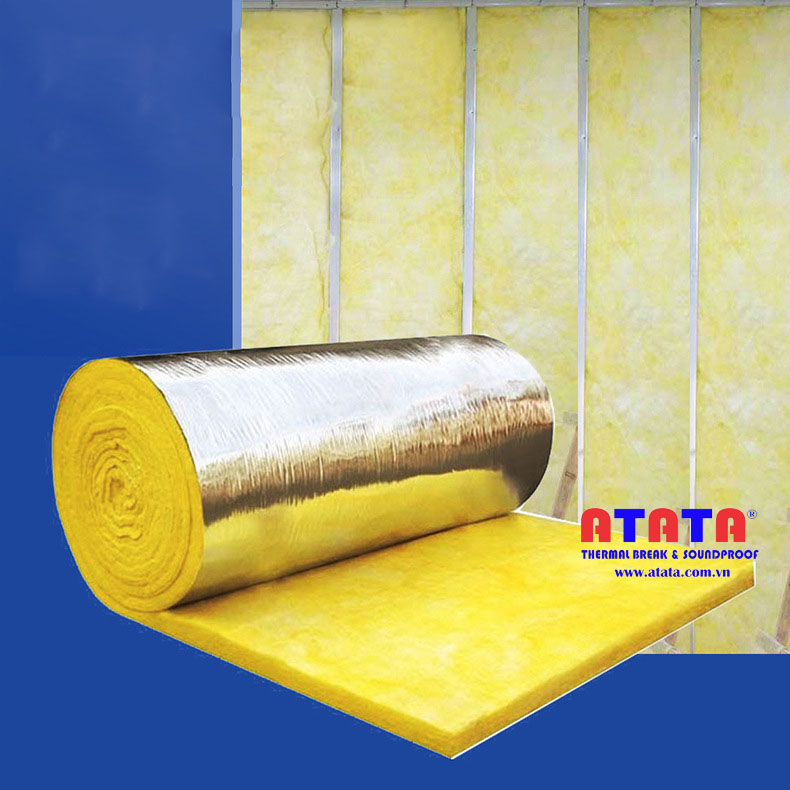

– Stage 2: Put the shaped rockwool pipe on the hot and cold pipe to be wrapped

– Stage 3: Use fixed wire or drawstring

– Stage 4: Wrap the shell to protect the inbox

– Stage 5: Checking for gaps and gluing silicon

Conclude

Submit request for quotes and product information

Hot tube insulation is very important to help the piping system operate safely, ensuring life and economy. What steps does this process take? What materials should be prepared? Construction done like? Today ATATA Insulation will guide you in detail how to insulate and insulate hot and cold piping. Through this detailed article you will know the following:

Prepare materials to insulate hot and cold piping

Ensuring safety for engineers performing works?

Steps to carry out construction and installation of pipe insulation

We will use the insulated tube to carry it out. If you do not understand this material, please see: What Is Insulated Heat Insulation Pipe?