General information

Insulated flexible duct:

Structure

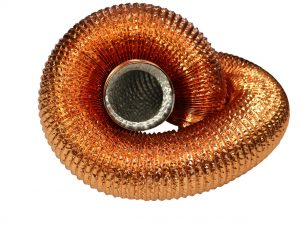

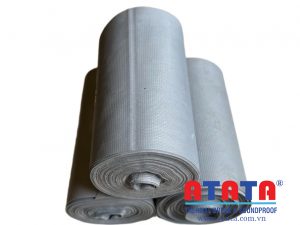

It is a type of duct made from many layers of aluminum attached to reinforced steel wire, so it is elastic and flexible. In the middle is a 25mm thick layer of insulating glass wool with a density of 22Kg/m3, the outermost layer is covered with a layer of white foil.

Insulated aluminum pipes are highly elastic, airtight and can be easily installed on round, oval or rectangular pipe ends. In case of fire, toxic gases are reduced.

This is a product directly manufactured and exclusively distributed by our company in the Vietnamese market. The product is trusted and used by many customers who are Mechanical and Electrical companies because of its good quality and more competitive price compared to similar products on the market.

| Các chỉ tiêu (PROPERTIES) | Thông số |

| Đường kính ống (Diameter Range) | 100-600mm |

| Nhiệt độ (Temperature Range) | -30 ~ +435 ºC |

| Vận tốc dòng khí (Tối đa) Velocity Of Air Flow (Max.) | 30 m/s |

| Áp suất làm việc (Working Pressure) | 2500 Pa |

| Bán kính uốn cong (Bending Radius) | 0.54*D |

| Chiều dài tiêu chuẩn (Standard Length) | 10 m/ống |

Structure and operating principle

Insulated flexible duct is usually made of 3 main layers:

Outer layer: Made of aluminum or aluminum alloy, has high durability, withstands environmental impacts and is easy to clean.

Middle layer: Is the insulation layer, usually made of glass wool or other insulating materials. This layer helps prevent heat loss, minimize noise and ensure cooling/heating efficiency.

Inner layer: Is the layer in direct contact with the air flow, usually made of anti-static and non-polluting materials.

The operating principle of insulated flexible ducts is based on the flexible flow of air through the pipes. The insulation layer helps maintain the temperature of the air inside the pipe, while minimizing condensation.

Outstanding advantages

Flexibility: Easy to bend, install and adjust to any space.

Good insulation: Minimizes heat loss, saves energy and ensures effective cooling/heating.

Good sound insulation: Minimizes noise, creates a quiet working and living environment.

Durable: Withstands environmental impacts, has a long life.

Easy to clean: Smooth surface, easy to clean.

Safe: Does not contain toxic substances, environmentally friendly.

Application

Insulated flexible ducts are widely used in the following ventilation systems:

Air conditioning systems: Conduct cold/hot air to rooms and areas that need cooling/heating.

Factory ventilation system: Provides fresh air, exhausts exhaust, ensures a clean working environment.

Kitchen ventilation system: Exhausts odors, grease smoke, ensures fresh air.

High-rise building ventilation system: Provides fresh air for apartments and offices.

Choosing insulated flexible ducts

When choosing insulated flexible ducts, you need to pay attention to the following factors:

Size: Depends on air flow and area to be ventilated.

Material: Choose materials suitable for environmental conditions and technical requirements.

Insulation layer thickness: Depends on insulation requirements.

Manufacturer: Choose products from reputable brands with guaranteed quality.

Conclusion

Insulated flexible ducts are a smart and effective solution for ventilation systems. With many outstanding advantages, this product is increasingly popular and widely used in construction projects.

Contact

DETI CO ., LTD

Factory : Atata Building, Yen Son IZ , Quoc Oai Dist, Ha Noi City

Office : Shop-House b5-20, Vinhomes Gardenia Ham Nghi, Nam Tu Liem District, Ha Noi City.

Hotline : 0913.554.030 – 0904 698 379 – 0936 382 469

Website : prodetech.vn ; beeflex.com.vn ; nanoflex.com.vn ;atata.com.vn ;3wtape.vn ; microflex.com.vn