Info :

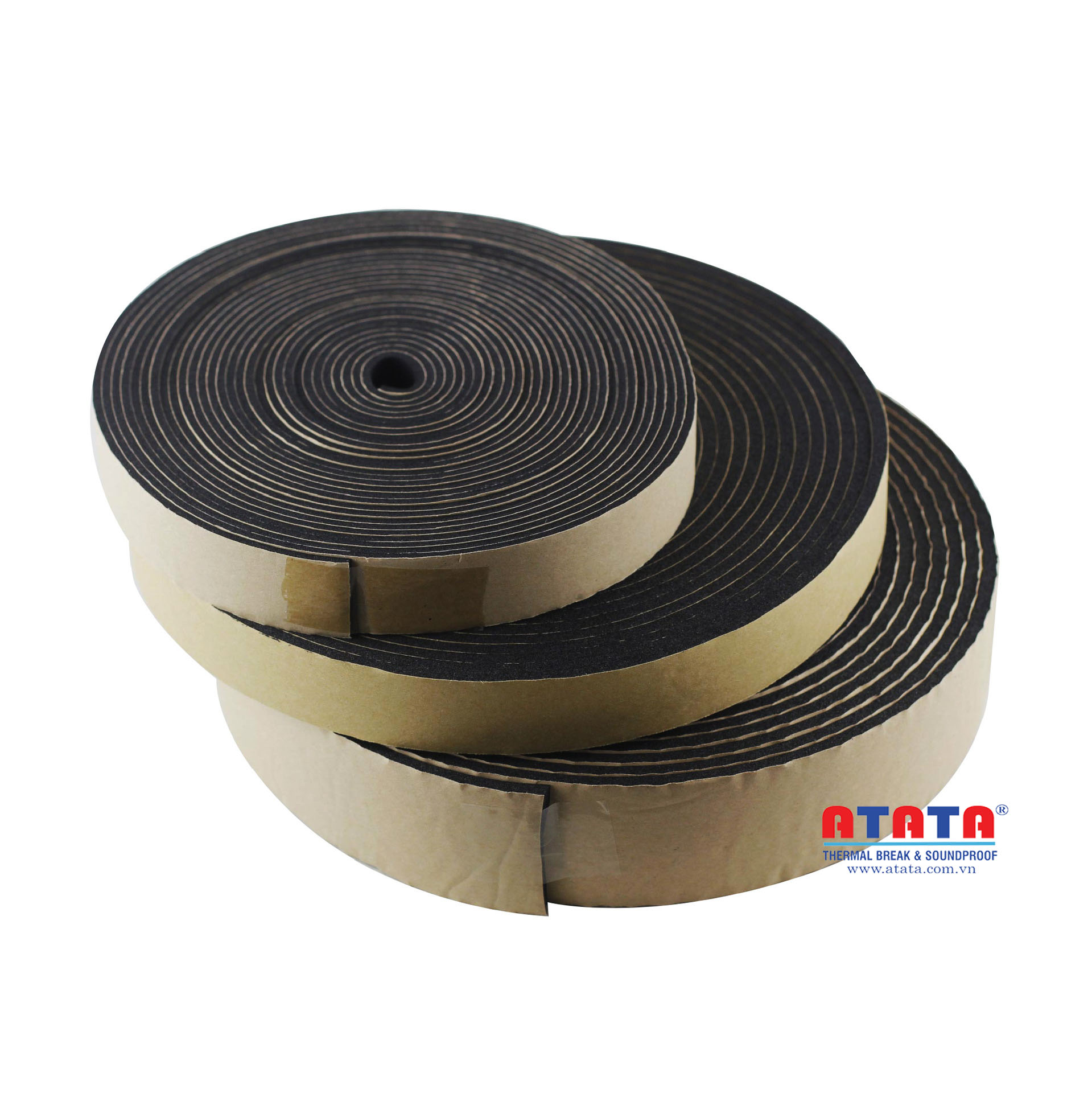

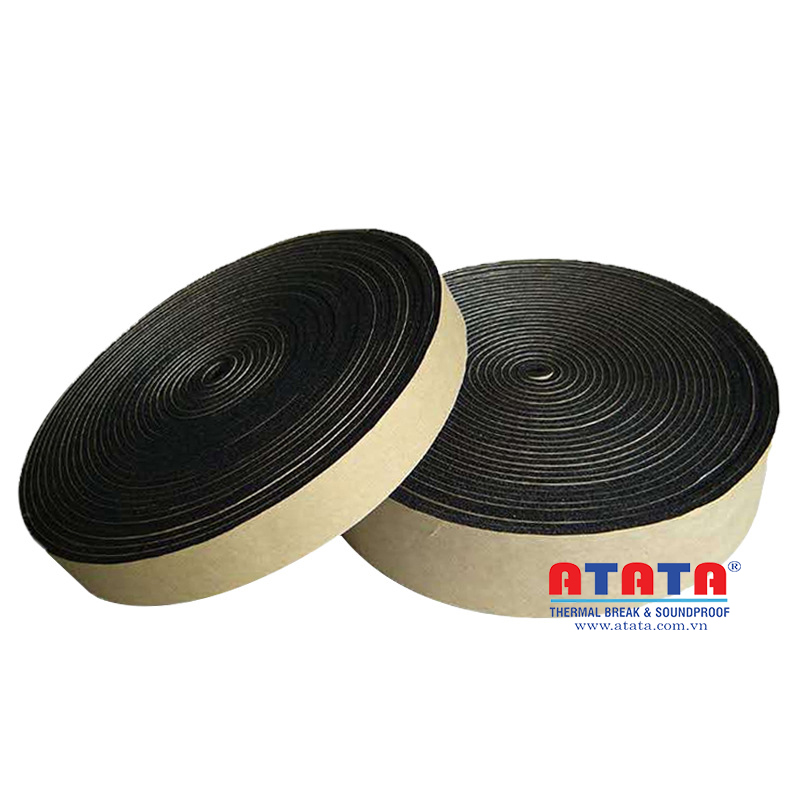

ATATA duct seals are specially designed to seal duct connections, eliminating the risk of air leaks through joints. Superior compressive resistance, no deformation during operation, maintain stable and long-lasting function. ATATA duct seals are available as pre-cut rolls of various sizes to suit all duct flange standards. Manufactured from foam rubber materials meeting the fire protection standards, with physical cross-linking, the absolute sealed structure helps to completely prevent the penetration of liquids and moisture, extending the life of the product. . Built-in glue in factory, specially designed can be used in many different temperature conditions, saving maximum costs and time during installation.

Detail :

Density 85 kg / m3

Thickness :5mm

Width: W: 25mm; 30mm; 35mm; 50mm; 200mm; 300mm

Length: L = 9.14m

Thermal conductivity coefficient 0.034 W / m.K

Fire protection standards: ASTM D6435, BS 476 part7, UL 94

Acrylic adhesive and basic solvent

Silicone paper liner

Traction force, compression ≥3-6H

Adhesion to the shell kg / 25mm 1.6 ± 0.2kg

Operating temperature range = -50 ° C – + 110 ° C

Why should you use NBR duct gaskets?

NBR duct gaskets are a popular and reliable choice in ventilation and air conditioning systems. NBR (Nitrile Butadiene Rubber) material offers many advantages over other types of gaskets, helping to increase the efficiency and durability of the system.

1. Good oil and chemical resistance:

NBR has excellent resistance to oil, grease and many other chemicals. This is especially important in environments exposed to lubricants or chemicals.

Helps the gasket to be more durable in harsh working conditions, prolonging the product’s life.

2. High durability, good elasticity:

NBR gaskets have high mechanical strength, withstand tensile, compressive and abrasion forces well.

Good elasticity helps the gasket fit tightly to the duct, effectively preventing air leakage.

3. Good heat resistance:

NBR can withstand temperatures ranging from -30°C to 120°C, suitable for many different environmental conditions.

Helps the gasket stabilize its shape and function during use.

4. Anti-aging:

NBR can resist the aging process caused by oxygen, ozone and other environmental factors.

Helps the gasket maintain its elasticity and function for a long time.

5. Good insulation and soundproofing:

NBR gaskets have good insulation and soundproofing, helping to reduce heat loss, reduce noise, and create a comfortable working and living environment.

6. Diverse sizes, easy to construct:

NBR gaskets come in many different sizes, easy to choose and cut to fit all types of air ducts.

Easy to construct, no high technical requirements.

Contact