Information:

ATATA duct gaskets are specially designed to seal duct connections, eliminating the risk of air leakage through joints.

Excellent compression resistance, no deformation during operation, maintaining stable and long-term function.

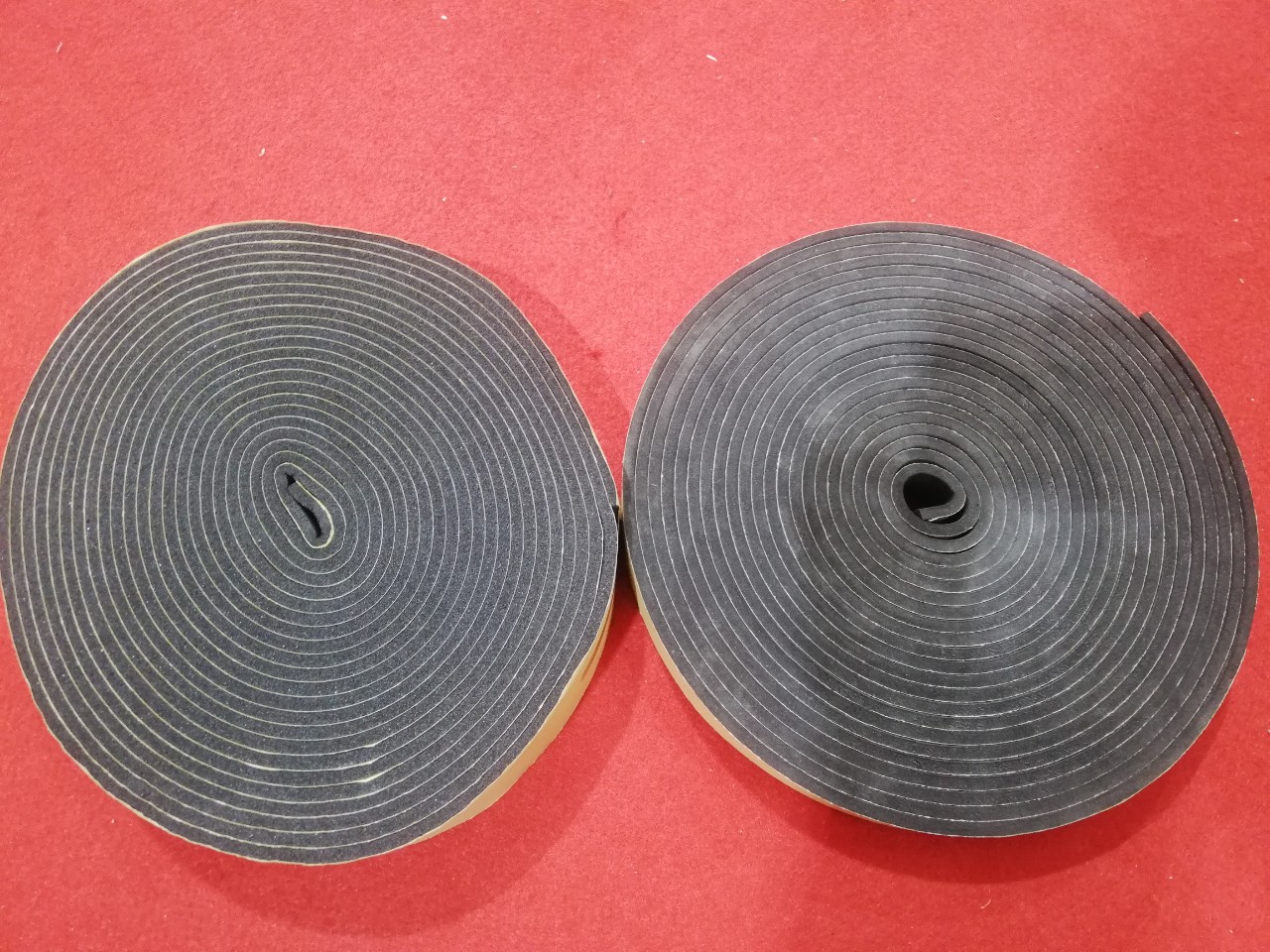

ATATA duct gaskets are available in pre-cut rolls with various sizes to suit all duct flange standards. Made from fire-resistant foam rubber material, with physical cross-linking, the absolutely sealed structure completely prevents the penetration of liquids and moisture, prolonging the life of the product.

The factory-integrated adhesive is specially designed to be used in a variety of temperature conditions, saving maximum cost and installation time.

Details:

PE component

Density: 28 kg/m3 – 35 kg/m3

Thickness: 3mm and 5mm

Length and width: According to customer’s request

Thermal conductivity: 0.033W/mK

Fire protection standards: ASTM E84, ASTM D6435, BS 476 part 7, UL 9

Acrylic adhesive and basic solvent

Silicone backing paper

Tensile, compressive strength ≥3-6H

Adhesion to the shell kg/25mm 1.6 ± 0.2kg

Operating temperature range = -20 ° C – + 85 ° C

Applications of PE duct gaskets

Connecting duct sections: Ensuring tightness, preventing air and dust leakage.

Insulating ducts: Reducing heat loss, helping the cooling/heating system operate more efficiently.

Reducing noise: Absorbing sound, reducing noise emitted from the ventilation system.

Protecting ducts: Preventing impact, scratches, prolonging the life of the duct.

Notes when using PE duct gaskets

Choose the right type of gasket:

Thickness: Depending on the gap size and insulation and soundproofing requirements, choose a gasket with the right thickness.

Material: There are many types of PE gaskets, each with different characteristics. You should choose a gasket with good elasticity, resistant to high temperatures and chemicals.

Surface preparation:

The duct surface needs to be cleaned and dried before gluing the gasket.

Remove obstacles such as dirt and grease to ensure the best adhesion.

How to paste:

Measure and cut: Measure the gap size to be pasted, cut the gasket to fit.

Paste evenly: Paste the gasket evenly, avoid leaving air bubbles.

Press tightly: Use a heavy object or specialized tool to press the gasket tightly onto the duct surface, ensuring a tight seal.

Check: After pasting, re-check the joints to make sure there are no gaps.

Other notes

Environmental conditions: PE gaskets can withstand high temperatures, but should not be exposed to direct fire or excessively high heat sources.

Storage: PE gaskets should be stored in a dry, cool place, away from direct sunlight.

Shelf life: The lifespan of PE gaskets depends on the conditions of use and product quality.

Summary

PE duct gaskets are a simple but very useful material in improving the performance of ventilation and air conditioning systems. By following the above notes, you can ensure the most effective installation and use of PE gaskets.

Contact

DETI CO ., LTD

Factory : Atata Building, Yen Son IZ , Quoc Oai Dist, Ha Noi City

Office : Shop-House b5-20, Vinhomes Gardenia Ham Nghi, Nam Tu Liem District, Ha Noi City.

Hotline : 0913.554.030 – 0904 698 379 – 0936 382 469

Website : prodetech.vn ; beeflex.com.vn ; nanoflex.com.vn ;atata.com.vn ; microflex.com.vn